技术

- 分析与建模 - 机器学习

适用行业

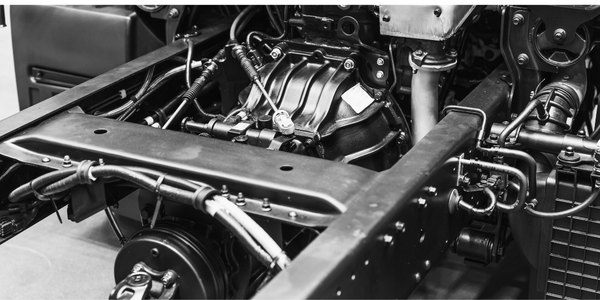

- 汽车

适用功能

- 离散制造

用例

- 柔性制造

服务

- 数据科学服务

- 系统集成

客户

上汽通用

关于客户

汽车OEM。

挑战

目前,汽车智能制造领域面临两大难点和痛点:

- 一是生产线设备容易出现故障,影响严重。当前产线设备一旦因故障停机,将影响生产节奏,降低产量,最坏的情况下会导致停产,给厂家造成巨大损失。监测生产设备的性能状态和预测故障是保证设备可靠性以实现正常生产运行的关键。

- 二是传统单条生产线难以实现自动化、柔性化生产转换。传统的多品种制造需要单独建线,产线建设成本高,新品上市周期长,越来越难以适应多品种、变批次、均等的要求注重研发生产,混线生产模式。

解决方案

制造全过程设备健康状况评估实施方案针对传统数控机床在预测建模过程中因机床异质性导致的数据模型复杂、特征提取困难、模型迁移能力差等问题,公司专注于传感器信号处理,开展诸如传感器信号处理等关键技术研究。如特征提取、特征优化和健康评估计算。通过建设车间级5G网络,对设备加工全过程进行数据采集,建立设备加工数据库。同时采用深度学习和深度迁移学习技术,实现对数控机床在多种工况下的自适应状态的评估和预测。

多品种多规格产品转批量柔性联线生产的实现方案。多品种、多规格产品的柔性联线生产,是通过在生产变更时对整条生产线的设备、工艺、物流等因素进行动态重新配置来完成的。公司应用人工智能技术,研发柔性生产变更智能生产调度算法、关键技术和装备,构建生产线子系统、数据采集子系统、柔性生产变更子系统、生产控制系统等多个子系统。其中,生产管控系统根据车间高速工业网络的实时数据,动态协调设备、技术、物流等生产资源,完成自动化、灵活的生产变更。

运营影响

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

Monitoring of Pressure Pumps in Automotive Industry

A large German/American producer of auto parts uses high-pressure pumps to deburr machined parts as a part of its production and quality check process. They decided to monitor these pumps to make sure they work properly and that they can see any indications leading to a potential failure before it affects their process.