- Analytics & Modeling - Machine Learning

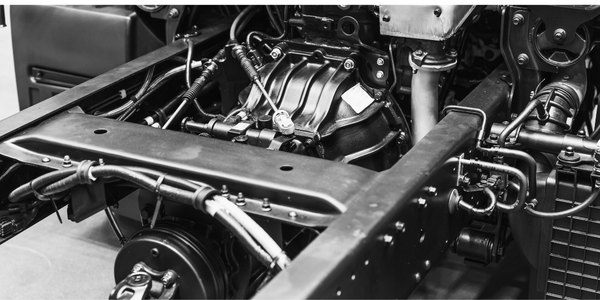

- Automotive

- Discrete Manufacturing

- Flexible Manufacturing

- Data Science Services

- System Integration

SAIC-GM

Automotive OEM.

At present, the field of automotive intelligent manufacturing is facing two major difficulties and pain points:

- First, the production line equipment is prone to failure and has a serious impact. Once the current production line equipment is shut down due to a fault, it will affect the production rhythm and reduce the output, or cause production stoppage in the worst case, causing huge losses to the manufacturer. Monitoring the performance status of production equipment and predicting faults is the key to ensuring the reliability of equipment to achieve normal production and operation.

- Second, it is difficult to realize automatic and flexible production changeover for traditional single-production lines. The traditional multi-variety manufacturing needs to build a separate line, the cost of production line construction is high, and the new product launch cycle is long, and it is increasingly difficult to adapt to the requirements of multi-variety, variable batch, equal emphasis on research and production, and mixed-line production mode.

Implementation plan for equipment health status assessment in the whole process of manufacturing. In view of the complex data models, difficult feature extraction, and poor model migration ability caused by machine tool heterogeneity in the process of prediction and modelling of traditional CNC machine tools, the company focuses on sensor signal processing, carry out research on key technologies such as feature extraction, feature optimization and health assessment calculation. By building a workshop-level 5G network, data collection is carried out in the entire process of equipment processing to establish a processing database of equipment. At the same time, deep learning and deep transfer learning technologies are used, realising the assessment and prediction of the adaptive state of CNC machine tools under multiple working conditions.

The realization plan of flexible co-line production of multi-variety and specification products changing to batches. The flexible co-line production of multi-variety and specification products is completed by dynamically reconfiguring the equipment, process, logistics and other factors of the whole production line when changing production. The company applies artificial intelligence technology to develop intelligent production scheduling algorithms, key technologies and equipment for flexible production change, and build multiple subsystems, including production line subsystem, data acquisition subsystem, flexible production change subsystem and production control system. Among them, the production management and control system dynamically coordinates production resources such as equipment, technology, and logistics according to the real-time data from the workshop's high-speed industrial network to complete automatic and flexible production changes.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.