技术

- 分析与建模 - 机器学习

- 分析与建模 - 预测分析

- 基础设施即服务 (IaaS) - 其他

- 网络与连接 - 网关

适用行业

- 石油和天然气

适用功能

- 维护

用例

- 机器状态监测

- 预测性维护

客户

村庄

关于客户

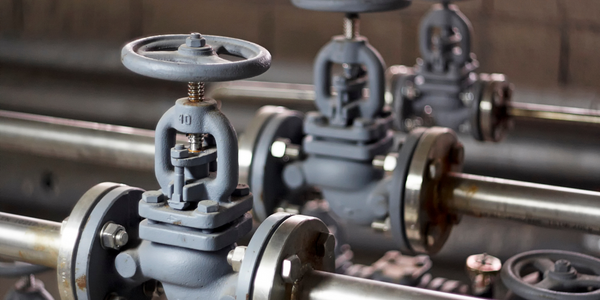

Ham-Let 是阀门、配件和仪表的领先制造商。

挑战

Ham-Let 是阀门、配件和仪表的领先制造商。该行业的主要挑战之一是识别故障并在造成任何损坏之前关闭适当的阀门。然而,识别故障原因并快速隔离阀门通常是一项艰巨的任务。

解决方案

过去的阀门有一个简单的功能:允许流量或关闭流量。智能阀能够使用采集的声学数据持续监测当前隔膜状况,从而实现自主预测性维护。

H800L 物联网阀门是一种工业解决方案,包括阀门和网关设备管理。除了制造和测试数据之外,还可以检索每个阀门的参数和历史数据,包括阀门打开和关闭的次数。

此外,通过使用机器学习和音频机器学习模型,我们可以分别分析阀门的打开和关闭参数,从而识别异常或异常情况。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Taking Oil and Gas Exploration to the Next Level

DownUnder GeoSolutions (DUG) wanted to increase computing performance by 5 to 10 times to improve seismic processing. The solution must build on current architecture software investments without sacrificing existing software and scale computing without scaling IT infrastructure costs.

Case Study

Remote Wellhead Monitoring

Each wellhead was equipped with various sensors and meters that needed to be monitored and controlled from a central HMI, often miles away from the assets in the field. Redundant solar and wind generators were installed at each wellhead to support the electrical needs of the pumpstations, temperature meters, cameras, and cellular modules. In addition to asset management and remote control capabilities, data logging for remote surveillance and alarm notifications was a key demand from the customer. Terra Ferma’s solution needed to be power efficient, reliable, and capable of supporting high-bandwidth data-feeds. They needed a multi-link cellular connection to a central server that sustained reliable and redundant monitoring and control of flow meters, temperature sensors, power supply, and event-logging; including video and image files. This open-standard network needed to interface with the existing SCADA and proprietary network management software.

Case Study

Refinery Saves Over $700,000 with Smart Wireless

One of the largest petroleum refineries in the world is equipped to refine various types of crude oil and manufacture various grades of fuel from motor gasoline to Aviation Turbine Fuel. Due to wear and tear, eight hydrogen valves in each refinery were leaking, and each cost $1800 per ton of hydrogen vented. The plant also had leakage on nearly 30 flare control hydrocarbon valves. The refinery wanted a continuous, online monitoring system that could catch leaks early, minimize hydrogen and hydrocarbon production losses, and improve safety for maintenance.