Cerro Vanguardia Improves Management, Streamlines Access to Documents and Boosts Information Security with SE Suite

公司规模

Large Corporate

地区

- America

国家

- Argentina

产品

- SE Document

- SoftExpert Excellence Suite (SE Suite)

技术栈

- Document Management System

- Web-based Software

实施规模

- Enterprise-wide Deployment

影响指标

- Productivity Improvements

- Cost Savings

- Customer Satisfaction

- Digital Expertise

技术

- 应用基础设施与中间件 - 数据交换与集成

- 应用基础设施与中间件 - 数据可视化

- 功能应用 - 企业资源规划系统 (ERP)

适用行业

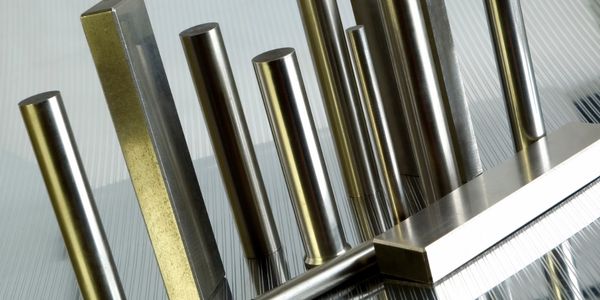

- 矿业

- 金属

适用功能

- 质量保证

- 商业运营

服务

- 软件设计与工程服务

- 系统集成

关于客户

Cerro Vanguardia is a gold and silver deposit with a mining concession covering approximately 512 km2 of surface. Located in the province of Santa Cruz in Argentina, it is one of the country's main precious metal mines. The mining company processes 980,000 tons of iron ore per year and produces an annual average of 6.8 tons of gold and 68 tons of silver during the entire operation. The final product consists of bars containing 10% gold and 90% silver, which are refined abroad to be used in applications such as jewelry, watches, electronic devices, coins and decorative objects, among others.

挑战

Due to the company's organizational structure, the number of employees and different departments, there is a high volume of documents circulating around the mining company. Several different procedures were created, prompting Cerro Vanguardia to seek a solution that could help it manage its documents, making them easier to find and facilitating their traceability. Furthermore, the mining company needed a specific software solution to help it ensure continued compliance with the Environment, Health and Safety System and with the ISO 14001:2004, ISO 9001 and OHSAS18001:2007 standards.

解决方案

After doing some market research, SoftExpert Excellence Suite (SE Suite) stood out from its competitors and was chosen as the best solution for controlling and managing documents. With the SE Document solution, Cerro Vanguardia is able to automate the creation and revision of documents during all their phases (editing, consensus, approval and acceptance), ensuring the complete monitoring of all actions affecting documents throughout their entire lifecycle. SE Document also guaranteed a high level of standardization and organization of the document archive based on the operating rules defined by the company (nomenclature, safety, document temporality, etc.), providing an effective mechanism for document identification, recovery and control. This ensures that Cerro Vanguardia will have updated versions constantly available for the right people whenever required.

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.

Case Study

Continuous Casting Machines in a Steel Factory

With a very broad range of applications, steel is an important material and has been developed into the most extensive alloy in the engineering world. Since delivering high quality is absolutely crucial for steel plants, ensuring maximum productivity and the best quality production are the keys to competitiveness in the steel industry. Additionally, working conditions in steel factories are not suitable for workers to stay in for long periods of time, so manufactures usually adopt various machines to complete the steel production processes. However, the precision of these machines is often overestimated and the lack of flexibility also makes supervisors unable to adjust operating procedures. A renowned steel factory in Asia planned to improve its Distributed Control System (DCS) of furnaces as well as addressing the problem of insufficient accuracy. However, most well-known international equipment suppliers can not provide a satisfactory solution and local maintenance because the project needed new technologies to more accurately control equipment operations. By implementing Advantech’s automated monitoring and control solution, steel factories can not only improve the manufacturing processes but can also allow users to add additional functions to the existing system so as to make sure the operation runs at high efficiency.

Case Study

Automated Predicitive Analytics For Steel/Metals Industry

Asset to be monitored: Wire Compactor that produces Steel RebarCustomer Faced The Following Challenges:Dependent upon machine uptime.Pressure cylinders within the compactor fail to control compression and speed causing problems in binding the coil.Equipment failure occurs in the final stage of production causing the entire line to stop, can you say bottleneck?Critical asset unequipped with sensors to produce data.