技术

- 分析与建模 - 虚拟和增强现实(AR/VR)软件

- 可穿戴设备 - 增强现实(AR)眼镜/耳机/控制器

用例

- 增强现实

- 混合现实

关于客户

本案的客户是 Skriduklaustur,这是冰岛东部的一处历史遗址,其中世纪遗址可以追溯到 16 世纪。该遗址是一座 16 世纪修道院遗迹的所在地,这是近年来最广泛的考古研究之一(2002 年至 2012 年间进行的)的发现。斯克里杜克劳斯特是 CINE See The Past | CINE 的一部分。想象未来项目,旨在使遗产网络对游客更加可见和有吸引力。该景点吸引了有兴趣探索和了解修道院及周边地区历史的游客和历史爱好者。

挑战

斯克里杜克劳斯特 (Skriduklaustur) 是一处历史古迹,其中世纪遗址可追溯至 16 世纪,在使其遗产网络更加引人注目方面面临着挑战。作为 CINE 的一部分,回顾过去 |在“想象未来”项目中,Locatify 受委托帮助提高位于冰岛东部 Fljotsdalur 山谷 Skriðuklaustur 的 16 世纪修道院的知名度和游客参与度。主要挑战是创造一种互动且引人入胜的方式,让游客探索和了解历史遗址,同时保留遗址的完整性和真实性。

解决方案

Locatify 使用增强现实 (AR) 技术开发了一种创新解决方案,以增强 Skriðuklaustur 的游客体验。客人可以使用平板电脑探索该地区。该平板电脑配备了传感器,可以触发与周围区域相关的 AR 挑战。玩家首先自定义自己的玩家角色,然后使用平板电脑探索该区域。当他们在遗址周围移动时,平板电脑中的传感器会触发 AR 挑战,提供有关周围废墟的信息和背景。该解决方案不仅使遗产网络更加可见,而且还为游客提供了一种互动且引人入胜的方式来了解该遗址的历史。

运营影响

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

How ScopeAR's Technology Helped Increase Efficiency by 30%

Scope AR collaborated with one of their large industrial clients to perform a side-byside comparison of Scope AR’s WorkLink software, an Augmented Reality software, versus using traditional paperbased methods to create manufacturing instructions. The client chose a complex assembly process for a proprietary spring-loaded hatch.The assembly process contained over thirty steps that involved things such as fitting components at specific angles to ensure proper assembly, screwing down different screw types in correct locations, and grabbing parts that had similar exteriors.The client chose this assembly process because it contained common steps that are frequently used in other processes as well as unique steps that are confusing and if done wrong would cause severe quality issues.

Case Study

Boeing Cuts Production Time by 25% with Skylight on Glass

130 miles of wiring go into every new Boeing 747-8 Freighter, tucked away overhead and underfoot from the cockpit to the wheel wells.Every Boeing aircraft, from the workhorse 737 to the new 787 Dreamliner, has multiple configurations, each with its own wiring scheme. In past years, technicians used “phone books” full of diagrams to do their work. Even with laptops, the same basic problem arised: constant look-away interruptions as workers got directions and cross-checked diagrams and schematics.

Case Study

AGCO is Increasing the Efficiency of its Manufacturing Programs Using Glass

The thorough inspection of a finished product is an essential step in the quality-control process. In the beginning, quality checklists were accessed using paper on clipboards. As technology improved, computers were utilized. But computers required additional time to access, and couldn’t be carried to the equipment being inspected. Tablets replaced computers, but were easily broken and expensive to replace.

Case Study

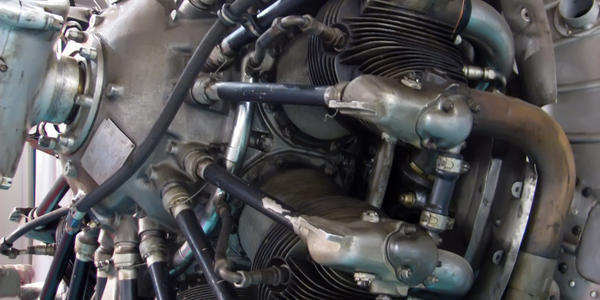

Getting the Torque Just Right Could Save Millions for Aerospace Companies

GE Aviation loses millions of dollars each year to errors made at key points during the assembly and overhaul of its engines. The costs show up in lost productivity, delays in testing, delays in customer deliveries, and the man-hours required to troubleshoot and correct faults. If errors arenʼt detected until after the engines are sent to customers, the repair costs exponentially increase.B-nuts are one such key manufacturing point. They play a critical role in aircraft engine fluid lines and hoses, providing a sturdy, reliable seal―but only if tightened and torqued properly. If not torqued properly, there will be a need for a maintenance do-over, cancelled flight, or even an in-flight shut down.