Technology Category

- Analytics & Modeling - Virtual & Augmented Reality Software

- Wearables - Augmented Reality Glasses, Headsets & Controllers

Use Cases

- Augmented Reality

- Mixed Reality

About The Customer

The customer in this case is Skriduklaustur, a historic site in East Iceland with ruins from the Middle Ages dating back to the 16th century. The site is home to the remains of a 16th-century monastery, which were revealed in one of the most extensive archaeological studies in recent years, conducted between 2002 and 2012. Skriduklaustur is part of the CINE See The Past | Imagine The Future project, which aims to make heritage networks more visible and engaging for visitors. The site attracts tourists and history enthusiasts who are interested in exploring and learning about the history of the monastery and the surrounding area.

The Challenge

Skriduklaustur, a historic site with ruins from the Middle Ages dating back to the 16th century, was facing a challenge in making its heritage network more visible. As part of the CINE See The Past | Imagine The Future project, Locatify was commissioned to help enhance the visibility and visitor engagement of the 16th-century monastery at Skriðuklaustur in Fljotsdalur Valley, East Iceland. The main challenge was to create an interactive and engaging way for visitors to explore and learn about the historic site, while also preserving the integrity and authenticity of the ruins.

The Solution

Locatify developed an innovative solution using Augmented Reality (AR) technology to enhance the visitor experience at Skriðuklaustur. Guests are provided with a tablet which they use to explore the area. The tablet is equipped with sensors that trigger AR challenges relating to the surrounding area. The player begins by customising their player character, and then uses the tablet to explore the area. As they move around the site, the sensors in the tablet trigger AR challenges that provide information and context about the surrounding ruins. This solution not only makes the heritage network more visible, but also provides an interactive and engaging way for visitors to learn about the history of the site.

Operational Impact

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

How ScopeAR's Technology Helped Increase Efficiency by 30%

Scope AR collaborated with one of their large industrial clients to perform a side-byside comparison of Scope AR’s WorkLink software, an Augmented Reality software, versus using traditional paperbased methods to create manufacturing instructions. The client chose a complex assembly process for a proprietary spring-loaded hatch.The assembly process contained over thirty steps that involved things such as fitting components at specific angles to ensure proper assembly, screwing down different screw types in correct locations, and grabbing parts that had similar exteriors.The client chose this assembly process because it contained common steps that are frequently used in other processes as well as unique steps that are confusing and if done wrong would cause severe quality issues.

Case Study

Boeing Cuts Production Time by 25% with Skylight on Glass

130 miles of wiring go into every new Boeing 747-8 Freighter, tucked away overhead and underfoot from the cockpit to the wheel wells.Every Boeing aircraft, from the workhorse 737 to the new 787 Dreamliner, has multiple configurations, each with its own wiring scheme. In past years, technicians used “phone books” full of diagrams to do their work. Even with laptops, the same basic problem arised: constant look-away interruptions as workers got directions and cross-checked diagrams and schematics.

Case Study

AGCO is Increasing the Efficiency of its Manufacturing Programs Using Glass

The thorough inspection of a finished product is an essential step in the quality-control process. In the beginning, quality checklists were accessed using paper on clipboards. As technology improved, computers were utilized. But computers required additional time to access, and couldn’t be carried to the equipment being inspected. Tablets replaced computers, but were easily broken and expensive to replace.

Case Study

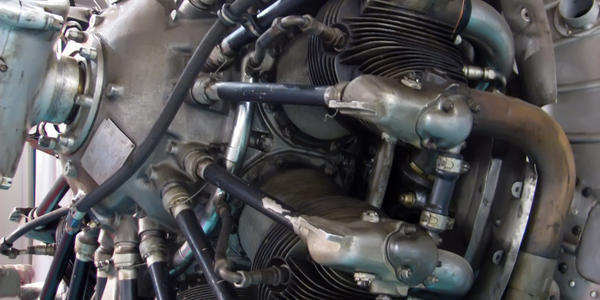

Getting the Torque Just Right Could Save Millions for Aerospace Companies

GE Aviation loses millions of dollars each year to errors made at key points during the assembly and overhaul of its engines. The costs show up in lost productivity, delays in testing, delays in customer deliveries, and the man-hours required to troubleshoot and correct faults. If errors arenʼt detected until after the engines are sent to customers, the repair costs exponentially increase.B-nuts are one such key manufacturing point. They play a critical role in aircraft engine fluid lines and hoses, providing a sturdy, reliable seal―but only if tightened and torqued properly. If not torqued properly, there will be a need for a maintenance do-over, cancelled flight, or even an in-flight shut down.