ж•ЉеЃЗиЗ™еК®еМЦдЄОжОІеИґ

- иГљжЇР

- зїіжК§

- дЇІеУБеЉАеПС

2016 еєіж•ЉеЃЗиЗ™еК®еМЦз≥їзїЯ (BAS) еЄВеЬЇдїЈеАЉ 536.6 дЇњзЊОеЕГпЉМйҐДиЃ°еИ∞ 2022 еєіе∞ЖиЊЊеИ∞ 991.1 дЇњзЊОеЕГпЉМ2017 еєіиЗ≥ 2022 еєізЪДе§НеРИеєіеҐЮйХњзОЗдЄЇ 10.73%

иµДжЦЩжЭ•жЇРпЉЪ еЄВеЬЇдЄОеЄВеЬЇ

2017 еєіжХідљУжЩЇиГљзЕІжШОеЄВеЬЇдїЈеАЉ 63.2 дЇњзЊОеЕГпЉМйҐДиЃ°еИ∞ 2023 еєіе∞ЖиЊЊеИ∞ 209.8 дЇњзЊОеЕГпЉМйҐДжµЛжЬЯеЖЕе§НеРИеєіеҐЮйХњзОЗдЄЇ 21.50%гАВ

иµДжЦЩжЭ•жЇРпЉЪ еЄВеЬЇдЄОеЄВеЬЇ

BACSз≥їзїЯзЪДж†ЄењГеКЯиГљжШѓдїАдєИпЉЯ

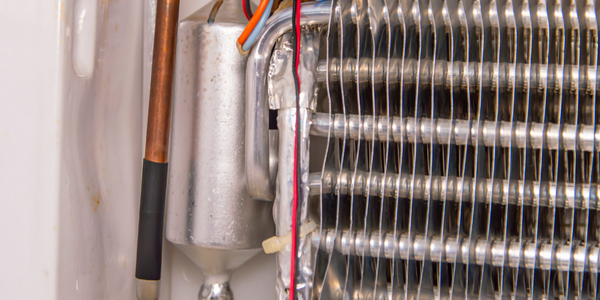

- дњЭжМБеѓєеїЇз≠СзЙ©зОѓеҐГзЪДжОІеИґ

- ж†єжНЃеН†зФ®зОЗеТМиГљжЇРйЬАж±ВињРи°Мз≥їзїЯ

- зЫСжОІеТМзЇ†ж≠£з≥їзїЯзЪДжАІиГљ

- ж†єжНЃйЬАи¶БеПСеЗЇе£∞йЯ≥и≠¶жК•

BACS еПѓдї•жОІеИґеУ™дЇЫиЃЊжЦљпЉЯ

жЬЇжҐ∞з≥їзїЯгАБзЃ°йБУгАБзФµж∞Фз≥їзїЯгАБдЊЫжЪЦгАБйАЪй£ОеТМз©Їи∞Г (HVAC)гАБзЕІжШОжОІеИґгАБеЃЙеЕ®еТМзЫСиІЖгАБи≠¶жК•еТМзԵ楃гАВ

еУ™дЇЫдЉ†жДЯеЩ®йАЪеЄЄзФ®дЇОеРСзЙ©иБФзљСз≥їзїЯжПРдЊЫжХ∞жНЃпЉМеУ™дЇЫеЫ†зі†еЃЪдєЙдЇЖеЃГдїђзЪДйГ®зљ≤пЉЯ

дљОеКЯзОЗжИЦиГљйЗПжФґйЫЖгАБеЊЃеЮЛгАБеЃЙеЕ®еТМе§ЪеКЯиГљзЪДдЉ†жДЯеЩ®еПѓдї•йЩНдљОиµДжЬђжФѓеЗЇгАБйЩНдљОзїіжК§жИРжЬђеТМжЫіеЃєжШУйГ®зљ≤гАВжЭ•иЗ™дЉ†жДЯеЩ®зЪДжХ∞жНЃйАЪињЗжЧ†жХ∞дЄУжЬЙеТМеЉАжФЊеНПиЃЃйАЪињЗиЈѓзФ±еЩ®гАБзљСеЕ≥гАБиКВзВєеТМиЊєзЉШиЃ°зЃЧжЬЇињЫи°МиљђжНҐеТМдЉ†иЊУгАВзљСеЕ≥иљђжНҐеТМж°•жО•еНПиЃЃпЉМеєґйАЪињЗдЄ≠е§ЃеЈ•дљЬзЂЩеТМзІїеК®иЃЊе§ЗеЃЮзО∞еѓєеїЇз≠СзЙ©зЪДеЖЕйГ®жОІеИґгАВ

еУ™дЇЫеЫ†зі†еЃЪдєЙдЇЖзФ®дЇОйЫЖжИРзЪДдЇСеТМиЊєзЉШеє≥еП∞пЉЯ

зљСеЕ≥ињШйАЪињЗиЬВз™ЭжИЦ俕姙зљСињЮжО•е∞ЖеїЇз≠СзЙ©ињЮжО•еИ∞дЇСгАВдЇСжФѓжМБињЬз®ЛиЃњйЧЃгАБжЫійЂШзЇІеИЂзЪДеИЖжЮРдї•еПКдЄОзФµзљСеТМеЊЃзФµзљСзЪДйАЪдњ°гАВ

BACS зЪДеЯЇжЬђзїДжИРйГ®еИЖжШѓдїАдєИпЉЯ

дЉ†жДЯеЩ®пЉЪжµЛйЗПжЄ©еЇ¶гАБжєњеЇ¶гАБзЕІжШОж∞іеє≥гАБжИњйЧіеН†зФ®зОЗз≠ЙеАЉгАВ

жОІеИґеЩ®пЉЪдљњзФ®еЇФзФ®йАїиЊСеТМеПСйАБеСљдї§зЪДзЃЧж≥ХпЉМдїОжФґйЫЖзЪДжХ∞жНЃдЄ≠жњАеПСз≥їзїЯзЪДеУНеЇФгАВ

иЊУеЗЇиЃЊе§ЗпЉЪжЙІи°МжЭ•иЗ™жОІеИґеЩ®зЪДеСљдї§гАВ

йАЪдњ°еНПиЃЃпЉЪBACS зїДдїґдљњзФ®зЪДвАЬиѓ≠и®АвАЭгАВ

дї™и°®жЭњпЉЪзФ®дЇОжХ∞жНЃжК•еСКеТМдЄО BACS з≥їзїЯдЇ§дЇТзЪДзФ®жИЈзХМйЭҐгАВ

еУ™дЇЫдЄЪеК°жМСжИШдЉЪељ±еУНйГ®зљ≤пЉЯ

зФ±дЇОзїДзїЗзїУжЮДеРДдЄНзЫЄеРМпЉМжЙЊеИ∞и¶БеЃЙи£ЕзЪДжЬАдљ≥з≥їзїЯеТМдЉ†жДЯеЩ®жШѓдЄАй°єеЈ®е§ІзЪДжМСжИШгАВињЩжШѓдЄ™ж°ИжГЕеЖµгАВеП¶дЄАдЄ™жМСжИШжШѓеЕЛжЬНеПѓиГљеЗЇзО∞зЪДжљЬеЬ®еЃЙеЕ®йЧЃйҐШеТМйЂШйҐЭеИЭеІЛжКХиµДгАВ

ж°ИдЊЛз†Фз©ґ.