技术

- 功能应用 - 制造执行系统 (MES)

- 平台即服务 (PaaS) - 应用开发平台

适用行业

- 生命科学

适用功能

- 物流运输

用例

- 添加剂制造

- 需求计划与预测

关于客户

该客户是一家价值数十亿美元的全球护肤、化妆品、香水和护发产品制造商。他们为全球 150 个市场提供服务,并以其标志性品牌而闻名。他们的供需规划活动以前严重依赖手动流程和 Excel,没有专注于运营和战略视野的主生产规划功能。由于经常需要手动干预来估计促销、营销和新产品推出的影响,该公司在整合需求情况方面遇到了困难。

挑战

该客户是一家价值数十亿美元的全球护肤、化妆品、香水和护发产品制造商,在供应和需求规划活动中面临着重大挑战。这些活动严重依赖 Excel 和手动流程,而这在很大程度上取决于每个计划者的个人知识。该公司缺乏专注于运营和战略视野的总体生产规划能力。由于经常需要人工干预来估计促销、营销和新产品推出的影响,绘制综合需求图的过程既困难又耗时。供应计划/排程主要是一个顺序计划过程,其中制造网络的每个阶段都是一个接一个地计划的,并且没有集成材料约束。此外,需求预测过程中没有包含促销和产品发布。

解决方案

该公司采用了o9的云原生平台来克服这些挑战。该平台提供了对其需求情况的全面可见性,实现了流程自动化并减少了手动干预的需要。它为制造和分销启用了并发的材料和产能限制计划,确保了一个集成的、更可行的、更好执行的计划。该平台还允许直接在其上包含新产品发布日历,考虑内部和外部需求驱动因素,提供以单位和美元为单位的 360 度预测视图。企业知识图用于构建具有主生产调度的需求和供应知识模型。这允许在一个集成的响应平台上运行 2 到 12 个月的运营时间范围内的所有关键规划流程,取代了以前的系统 SAP APO。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

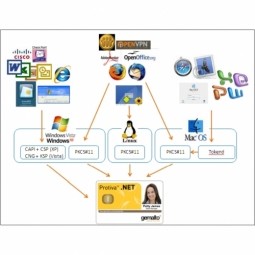

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

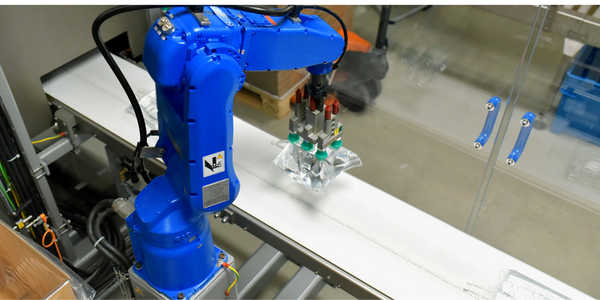

Flow Robotics: Scaling Up Production and Accelerating Product Development with IoT

Flow Robotics, a Danish manufacturer, developed flowbot™ ONE pipetting robots to alleviate the strain on bioanalysts in life-science laboratories and hospitals across Europe. These robots were designed to automate part of the testing process, speeding up the time it takes to produce results and reducing pressure on staff. However, the company faced challenges in scaling up production and accelerating product development. High workloads and physically challenging conditions have long been an issue for laboratory professionals. Flow Robotics estimates that around half of medical lab technicians carry out the same arm movements for at least a quarter of their working day. The American Society for Clinical Pathology reported that 85% of laboratory professionals feel burnt out; 36% struggle with inadequate staffing; and 32% face a heavy workload and pressure to complete all testing on time.

Case Study

Revolutionizing Aerospace Industry with 3D Printing: A 63% Lighter Titanium Part

GE Aviation, a renowned name in the aerospace industry, recognized the potential of 3D printing technology in transforming the sector. The primary challenge was to reduce the weight of the aerospace parts, which would directly impact the fuel costs. A lighter airplane would mean lower fuel consumption, leading to cost savings and a smaller carbon footprint. However, achieving this weight reduction without compromising the strength and functionality of the parts was a significant challenge. Traditional manufacturing methods were not able to provide the desired weight reduction while maintaining the required stiffness and strength of the parts. The challenge was to find a solution that could create strong, light, and functional aerospace parts.

Case Study

Material Intelligence at Ethicon: Sustaining Medical Device Manufacturability and Improving Patient Care

Ethicon, a world-class medical devices company, faced several challenges in its operations. The rapid selection of manufacturing materials compliant in global markets was critical to assure patients, practitioners, and purchasing organizations of the biocompatibility of their medical devices. Ensuring supply chain continuity and minimizing risks of obsolescence for medical devices due to regulatory changes were also crucial in meeting Ethicon’s ongoing commitment to maintaining patient care. Furthermore, the engineers at Ethicon were developing the next generation of medical devices and needed to access historical material data to accelerate new product development. The process of centralizing and digitalizing its materials information was a significant challenge that Ethicon needed to overcome.

Case Study

IWT's Transformation: Customizing with Efficiency in IoT

IWT, a company specializing in the design, manufacture, and installation of washing systems for the life sciences and pharmaceutical industries, faced a significant challenge in managing its wide product portfolio. The company manufactures 45 different models, 60% of which are customized to some degree. This high level of customization, combined with limited production quantities, necessitated a controlled process for managing the release of engineering changes. The goal was to achieve efficiency, reduce process time, and better coordinate production throughout the organization. The need for strict compliance in heavily regulated industries further complicated the situation. IWT's existing PLM journey with Dassault Systèmes’ SOLIDWORKS for 3D CAD and Enovia for managing CAD data and Bills of Materials (BOMs) was proving inadequate. The system had limited part classification, no workflow, and no tool to ensure data consistency. The management of non-CAD documents was also a challenge, with information often difficult to find and access.