公司规模

1,000+

地区

- Europe

国家

- Canada

- United States

产品

- iWay Service Manager

- SAP R/3

- GE Proficy Plant Applications

技术栈

- Microsoft Message Queue (MQ) services

- Microsoft service bus

实施规模

- Enterprise-wide Deployment

影响指标

- Cost Savings

- Productivity Improvements

技术

- 应用基础设施与中间件 - 数据交换与集成

- 功能应用 - 企业资源规划系统 (ERP)

适用行业

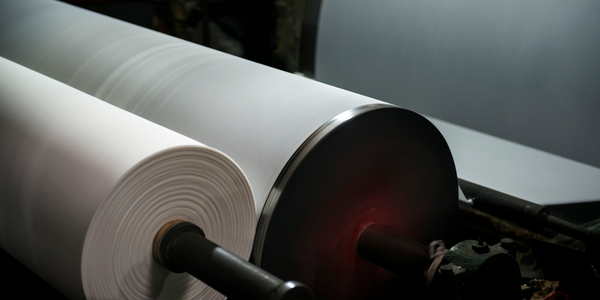

- 造纸

适用功能

- 离散制造

- 采购

用例

- 自动化制造系统

- 预测性维护

服务

- 软件设计与工程服务

- 系统集成

关于客户

Cascades is a company that produces, converts, and markets packaging and tissue products that are composed mainly of recycled fibers. The company was founded in 1964 and employs close to 12,000 people in more than 100 production units in North America and Europe. With its proven management philosophy, half a century of experience in recycling, and continuous efforts in research and development as driving forces, Cascades continues to deliver innovative products on which its customers rely.

挑战

Cascades, a packaging and tissue products manufacturer, was implementing SAP R/3 enterprise resource planning (ERP) applications across its numerous mills, plants, and paper manufacturing facilities. This was part of an enterprise-wide strategy to reengineer financials, procurement, purchasing, production planning, warehouse management, plant maintenance, and other essential business functions. However, a significant challenge in this multi-year SAP deployment involved integrating the new SAP environment with the existing infrastructure. Cascades needed integration technology to monitor shop floor equipment and seamlessly move data, messages, and transactions across this complex infrastructure.

解决方案

Cascades standardized on iWay to monitor variables within the production process, consolidate the results for offline analysis, and exchange real-time data for running payroll, executing plant floor processes, purchasing raw materials, etc. The Cascades Tissue Group uses GE Proficy Plant Applications to monitor machinery and gather statistics about physical conditions in the plants. Sensors on the equipment gather data about temperature, humidity, and other operating conditions that affect the quality of the finished products. The IT department uses iWay Service Manager to obtain log files of this information and send those files to a central data center for processing. The team deployed the SAP interfaces in two phases. In Phase 1, they created secure FTP channels to move legacy data into a multichannel architecture. These interfaces enabled plants to send and receive data between a legacy inventory system, a legacy production manufacturing system, and two SAP modules: SAP Order Management and SAP Planning.

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Wireless Improves Efficiency in Compressed Air Systems

Hollingsworth and Vose wanted to improve the efficiency of their compressed air system, lower the electricity expense component of manufacturing cost in their commodity industry, and conserve energy leading to lowered greenhouse gas emissions. Compressed air systems degrade over time and become leaky and inefficient. Hollingsworth and Vose wanted to increase the frequency of system inspections without paying the high cost of manual labor.

Case Study

Process Predictive Analysis in Pulp and Paper Mill

Common paper breaks consequently lead up to 60 minutes of downtime, delaying a potential $10K per hour of production value process. Thus, defective products cause financial and damage company's reputation. Improving quality and reducing defect rates can generate millions of dollars of revenue per year for your company.

Case Study

Industrial Video Monitoring for Security and Regulatory Compliance

Because of the Stevenson mill’s proximity to the Tennessee River, WestRock was required by the USCG to comply with the Maritime Security 33CFR (MARSEC) regulations. WestRock needed a video security system but wanted to add other applications not required by the government, such as video process monitoring, condition monitoring, and wireless network management. WestRock needed a reliable video solution to avoid the compliance fines and possible security risks – but the solution needed to be implemented in the most cost-effective manner possible.

Case Study

ECOsine Active Increased Reliability in the Paper Industry

The paper and pulp industry is interlinking intelligent hi-tech machines to highly efficient production lines. Higher power DC and AC motor drives perform the automation tasks. Every kind of interference that negatively affects the reliability and safety of the installation may lead to production downtime and consequently to significant financial losses. AC and DC motor drives are so-called non-linear loads as they draw a nonsinusoidal current from the grid. Resulting harmonics of current and voltage can interfere with the operation of nearby consumers and overload the electrical infrastructure. In this particular application, the load cycles of the drives often caused interruptions in the production process because of disturbances coupling into the fieldbus system.