技术

- 自动化与控制 - 分布式控制系统

- 平台即服务 (PaaS) - 设备管理平台

适用行业

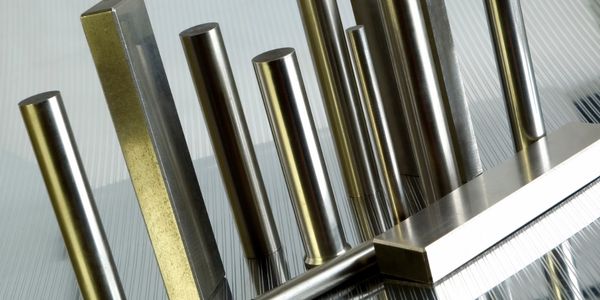

- 金属

适用功能

- 流程制造

用例

- 机器状态监测

- 过程控制与优化

客户

加铝国际

关于客户

Alcan International,加拿大世界领先的矿业公司和铝制造商。

挑战

加铝的日程安排很紧,要将其铝土矿从 2.2 吨扩大到 380 万吨氧化铝矿物加工精炼厂。 Alcan 面临的挑战包括平衡资本成本、最大限度地减少现场施工人员的数量、在不影响当前运营设施的情况下整合绿地和棕地设施,同时实现项目预算、进度和质量。

解决方案

加铝决定使用预组装模块 (PAM) 概念进行扩展,该概念使所有模块都可以在泰国和越南异地建造。通过使用艾默生的 DeltaV 和 AMS 设备管理器预先调试 FOUNDATION 现场总线设备,Alcan 显着减少了工时并节省了成本。软件组件 - DeltaV 和 AMS 设备管理器

收集的数据

Device Diagnostic Status, Labor Costs, Maintenance Requirements, Man Hours, Operating Cost

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.