Technology Category

- Infrastructure as a Service (IaaS) - Virtual Private Cloud

- Wearables - Virtual Reality Glasses, Headsets & Controllers

Applicable Functions

- Product Research & Development

Use Cases

- Time Sensitive Networking

- Virtual Prototyping & Product Testing

Services

- Hardware Design & Engineering Services

- Testing & Certification

About The Customer

Whirlpool Corporation is a leading global manufacturer and marketer of major home appliances. The company has a significant presence in India, where it operates a design center. Whirlpool is committed to innovation and quality, and it continually seeks ways to improve its products and processes. The company was looking to scale up its Indian design center's capacity to accommodate a greater commitment to virtual design, testing, and evaluation. However, the high licensing costs of technical solutions were a major deterrent. Whirlpool needed a solution that would allow it to increase its virtual design capacity without incurring prohibitive costs.

The Challenge

Whirlpool, a renowned home appliance manufacturer, was facing a significant challenge in scaling up the capacity of its Indian design center. The company wanted to commit more to virtual design, testing, and evaluation, but the high licensing costs of technical solutions were a major deterrent. The challenge was to find a cost-effective solution that would allow them to increase their virtual design capacity without incurring prohibitive costs. This was crucial for Whirlpool to maintain its competitive edge in the market and continue delivering high-quality appliances to its customers.

The Solution

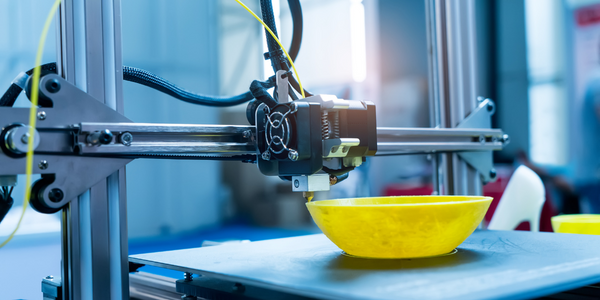

Whirlpool found its solution in the Altair Partner Alliance. This partnership enabled Whirlpool to utilize pre-processing, post-processing, solver, and fatigue analysis solutions all under one licensing platform. This innovative approach allowed them to perform Computational Fluid Dynamics (CFD) analysis using AcuSolve and fatigue analysis with nCode DesignLife. These tools were used to test the life of the steel components, marking a first for Indian appliance design teams. The Altair Partner Alliance's unique licensing system allowed more engineers to work on virtual prototyping simultaneously, leading to increased efficiency and cost savings.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Intralox Using Demo3D Case Study

Intralox strives to create significant economic value for our customers by optimizing their conveyance systems. Intralox wants to emulate real-world production environments for end users and OEMs working in multiple industries, including packaging, warehousing, parcel, beverage, brewery, food, tire, and consumer goods. They frequently had to perform physical tests to demonstrate to customers how ARB equipment would handle their products.

Case Study

General Dynamics Uses Wind River Simics to Meet NASA Challenge

In designing and building Fermi, the General Dynamics C4 Systems business unit was faced with a challenge: it needed to provide an environment that could support rigorous testing by multiple Fermi subsystem groups before the spacecraft hardware was available.