Technology Category

- Sensors - Temperature Sensors

- Sensors - Utility Meters

Applicable Industries

- Life Sciences

- Plastics

Applicable Functions

- Procurement

- Product Research & Development

Use Cases

- Last Mile Delivery

- Smart Lighting

Services

- Hardware Design & Engineering Services

- Testing & Certification

About The Customer

DSM – Bright Science. Brighter Living.™ Royal DSM is a global science-based company active in health, nutrition, and materials. By connecting its unique competences in Life Sciences and Materials Sciences, DSM drives economic prosperity, environmental progress, and social advances to create sustainable value for all stakeholders. DSM delivers innovative solutions that nourish, protect, and improve performance in global markets such as food and dietary supplements, personal care, feed, pharmaceuticals, medical devices, automotive, paints, electrical and electronics, life protection, alternative energy, and bio-based materials. DSM’s 23,500 employees deliver annual net sales of about 9 billion Euros. The company is listed on NYSE Euronext.

The Challenge

DSM Engineering Plastics, a global provider of high-performance plastics, faced a challenge in the LED lighting applications sector. The heat sinks used in these applications, primarily made of aluminum, were responsible for dissipating heat generated by LEDs to the environment. However, aluminum, despite being a good heat conductor, had limitations such as high costs related to machining die-cast parts, limited design freedom, recyclability issues, and weight. DSM sought to provide a plastic-based solution for heat sinks to overcome these issues. To find an optimal design for the heat sink made of polymer material and predict its thermal performance, DSM needed to model natural convection and radiation cooling, the mechanisms by which LED heat sinks dissipate heat to the environment. The challenge was to find a tool that could accurately simulate these processes and provide reliable results.

The Solution

DSM implemented AcuSolve, a product of Altair Engineering, in its development processes. AcuSolve is a general-purpose Computational Fluid Dynamics (CFD) based software capable of modeling a variety of heat and flow problems. DSM used AcuSolve to model natural convection and radiation cooling. To evaluate the cooling capacity of a polymer heat sink, AcuSolve was used alongside other valuable CAE tools. AcuSolve was able to model heat loss by natural convection, taking into account the heat loss to the air flow around the heat sink due to density differences of the air in proximity to the heat sink surface. It also accounted for air flow stagnation due to boundary layer effects, particularly when a heat sink was designed with too small fin-to-fin spacing. Furthermore, AcuSolve was able to model radiation heat loss, taking into account view factors for different parts of the heat sink using the hemicube algorithm. This allowed for the optimization of the heat sink design to maximize radiative heat loss to the environment.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Plastic Spoons Case study: Injection Moulding

In order to meet customer expectations by supplying a wide variety of packaging units, from 36 to 1000 spoons per package, a new production and packaging line needed to be built. DeSter wanted to achieve higher production capacity, lower cycle time and a high degree of operator friendliness with this new production line.

Case Study

Boiler Control System for Plastic Manufacturing Applications

Factory automation applications must be equipped to handle and monitor the myriads of information from attached devices. For plastic manufacturing applications, the boiler control system plays a critical role by gathering and regulating information to ensure production is accurate and smooth. In this particular case, the customer combines eight subsystems that include power meters, water meters, alarm output, displays, and I/O status to be controlled by several intelligent controllers with Modbus RTU interface. The Modbus TCP protocol is used for this application due to the distance. System Requirements: • Modbus serial to Modbus TCP translation • Multiple slaves/masters support • Automatic Modbus TCP response time detection

Case Study

Ascend Performance Materials Case Study

Ascend operations must access multiple software systems to manage day-to-day operations in an effective and secure manner. These systems generate large sets of data which contain critical information pertaining to management systems, planning and cost information in business systems and energy consumption. As a result, Ascend management was challenged with creating relevant reports reflecting performance measures in overall context of their operational process. The company’s previous process entailed collecting and analyzing data manually which was not effective, since the information collected was generated after the fact, and was too complex for collaborative use across the organization.

Case Study

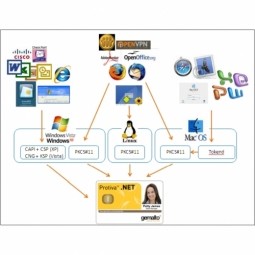

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Remake Enterprise-to-production System

The client was running a legacy material flow tracking system and wanted to replace the system with a more effective one as the system was increasingly expensive to maintain and support and also was not extendable. The client's IT landscape was filled with modern applications and it was difficult to interface the material flow tracking system with modern applications.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data