Technology Category

- Functional Applications - Manufacturing Execution Systems (MES)

- Networks & Connectivity - Ethernet

Applicable Industries

- Cement

- Life Sciences

Applicable Functions

- Product Research & Development

- Quality Assurance

Use Cases

- Additive Manufacturing

- Manufacturing Process Simulation

Services

- Testing & Certification

About The Customer

Guerrilla Gravity is a mountain bike manufacturing company based in Denver, Colorado. The company is committed to significantly improving mountain biking by building a community advocating for trail access, and creating innovative mountain bikes at democratized price points. Their most recent innovation is the Revved Carbon Technology, which represents a compelling combination of durable bikes that are also lightweight and high performance. The technology combines a new bike frame material and a new patent-pending manufacturing method, resulting in bikes that are 300% more impact resistant than other frames on the market that use traditional carbon fiber materials, while maintaining equivalent weight and stiffness properties.

The Challenge

Guerrilla Gravity, a mountain bike manufacturing company based in Denver, Colorado, faced a significant challenge in pioneering a new material application and technology without a roadmap. The company was experiencing rising demands and needed to meet schedule and production challenges. The launch of their innovative Revved Carbon Technology, which combines a new bike frame material and a new patent-pending manufacturing method, brought an additional set of challenges. The company had to scale production with increased demand, which was doubling year after year. The introduction of the new technology also posed the risk of unknown problems arising, putting launch schedules in jeopardy.

The Solution

Guerrilla Gravity turned to Altair's OptiStruct in the early design phase to enable a much more concise, high-performance solution. OptiStruct allowed Guerrilla Gravity to jump to a high-performance solution much quicker than a common iterative FEA process. The topology optimization capabilities allowed the designers to run multiple load cases and evaluate exactly where the plies were needed in the frame. This knowledge early on enabled Guerrilla Gravity to make critical decisions that influenced expensive manufacturing outcomes. Additionally, OptiStruct allowed the team to gain significant confidence going into physical testing; knowing that the frames had a high likelihood of passing the American Society for Testing and Materials (ASTM) standards on the first try.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

System 800xA at Indian Cement Plants

Chettinad Cement recognized that further efficiencies could be achieved in its cement manufacturing process. It looked to investing in comprehensive operational and control technologies to manage and derive productivity and energy efficiency gains from the assets on Line 2, their second plant in India.

Case Study

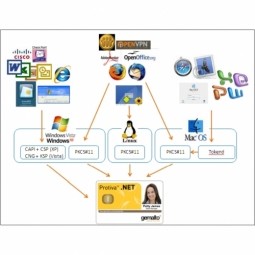

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

Digital Transformation of Atlanta Grout & Tile: An IoT Case Study

Atlanta Grout & Tile, a Tile, Stone & Grout restoration company based in Woodstock, Georgia, was facing challenges with its traditional business model. Despite steady growth over the years, the company was falling behind the web revolution and missing out on the opportunity to tap into a new consumer base. They were using independent software from different vendors for each of their department information and workforce management. This resulted in a lot of manual work on excel and the need to export/import data between different systems. This not only increased overhead costs but also slowed down their response to clients. The company also had to prepare numerous reports manually and lacked access to customer trends for effective business decision-making.

Case Study

Revolutionizing Construction Equipment Rental: A Case Study on ProsRent and ENO8

ProsRent, a startup that won the 'Best Financial Opportunity' and 'Best Pitch' at CodeLaunch 2016, aimed to revolutionize the way construction professionals source and rent heavy equipment. In the construction industry, project managers and contractors typically rent heavy equipment from supply companies. However, predicting inventory can be challenging, and finding the required equipment at the right time and place can be a hassle. If the preferred vendor doesn't have the required equipment, it results in wasted time and money in searching for it, often leading to higher costs due to non-preferred rates and increased delivery costs if the vendor is located far from the job site. Suppliers, on the other hand, desired access to a wider base of trusted renters that they didn't have to vet themselves and wanted to offer dynamic rental pricing based on demand and availability in their market. ProsRent's challenge was to produce a minimum viable product that was fast and first to market but also strong enough to engender loyalty and repeat business from the target market.