Technology Category

- Infrastructure as a Service (IaaS) - Cloud Middleware & Microservices

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- Apparel

- National Security & Defense

Applicable Functions

- Logistics & Transportation

- Quality Assurance

Use Cases

- Cybersecurity

- Tamper Detection

Services

- System Integration

- Testing & Certification

About The Customer

Spread Group is a tech-driven fashion and lifestyle provider that specializes in quality, customized apparel. Founded in Leipzig, Germany, the company operates on a global scale, manufacturing over 10 million products on demand for customers in 170 countries. Spread Group runs three distinct brands: Spreadshirt, TeamShirts, and Spreadshop. Its mission is to 'print ideas', connecting customers and corporates who want customized clothing with independent creators selling on-demand merchandise. The company employs over 1,000 skilled employees from 43 countries and operates four production sites in Europe and the US.

The Challenge

Spread Group, a global fashion and lifestyle provider, faced a significant challenge in maintaining its global scale and converting online clicks into physical products. The company, which operates three distinct brands, needed to weave delivery with security to ensure the smooth operation of its platform. With over 6.17 billion average monthly requests, finding a Content Delivery Network (CDN) to supercharge delivery was a top priority. Additionally, Spread Group needed a robust Web Application Firewall (WAF) that could work in harmony with its constantly evolving platform. The company had a good, internally developed security monitoring and observability infrastructure, but it was not viable long-term. A flexible WAF that could run in blocking mode was needed to provide more time to modernize vulnerable legacy components.

The Solution

Fastly provided Spread Group with a creative, tailored CDN solution in 2016. This solution included a clever chatbot, live logging for real-time insights, optimized A/B testing, and improved overall cache purging time. This feature set perfectly fit Spread Group’s Continuous Integration, Continuous Delivery, and Continuous Monitoring demands. Recently, Spread Group turned to Fastly’s Next-Gen WAF for integrated, intuitive security. The selection process was a collaborative effort, with senior platform security experts performing product evaluation and testing. Spread Group set up two testing sites for the evaluation, running various attack tooling tests manually and automatically to check which rules were enforced by the WAF. The Fastly Next-Gen WAF displayed a more discerning blocking approach than competitors, only blocking malicious requests, not business-critical functions. It also fitted smoothly with their existing security ecosystem.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

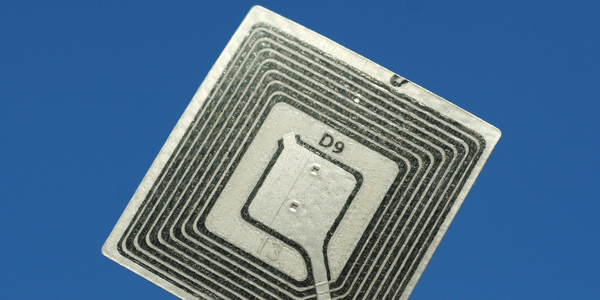

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

Case Study

Monitoring and Controlling Automatic Mixing and Dispensing Machines

As technology advances, textile manufacturing has been transformed from a labor-intensive to a partially or fully automated industry. Automation is significant in all segments of textile production - from spinning to printing, and textile machinery manufacturers are constantly searching for new technologies and automation processes will increase the productivity of their machines. The color paste mixing and dispensing machine is an essential part of the printing and dyeing process. With the advantage of automatically computerized controls and database management, the system can significantly improve its dispensing precision, working efficiency and production quality as well as reducing material consumption.

Case Study

Data Capture for Afghanistan Forces

Electronic equipments on the field of Afghanistan provided information on the status of the vehicle and to identify potential threats surrounding it to the British Force. The monitoring and interpretation of this data requires robust and sophisticated digitization for data capture and communication.