Technology Category

- Functional Applications - Inventory Management Systems

- Functional Applications - Manufacturing Execution Systems (MES)

Applicable Industries

- Finance & Insurance

- Life Sciences

Applicable Functions

- Facility Management

- Warehouse & Inventory Management

Use Cases

- Inventory Management

- Picking, Sorting & Positioning

Services

- System Integration

The Customer

Keltour Controls

About The Customer

Keltour Controls is a company based in Burlington, Ontario, that has specialized in control panel manufacturing since 1972. The company serves thousands of domestic and international customers and has expanded its offerings to include engineering, design, integration, programming, and commissioning systems in most major industries. Keltour has over 30 employees using Total ETO in their Burlington location, as well as some staff at their US facility. The company typically works on fixed-price projects and uses QuickBooks for accounting.

The Challenge

Keltour Controls, a company specializing in control panel manufacturing, faced several challenges in their operations. The company was struggling with time-tracking limitations that required accounting and payroll to re-enter staff hours after they were submitted. This process was not only time-consuming, resulting in several hours of additional work every week, but also caused a one-week lag in job labour costing and reporting. Additionally, Keltour needed a better system for tracking and real-time monitoring of their manufacturing data. The company also sought to improve their visibility of Work in Progress (WIP) and project invoicing by integrating it with their accounting data.

The Solution

Keltour Controls decided to implement Total ETO, a solution they had used 18 years prior. The company had tried implementing another system but faced issues with lack of math linking, logic, and vendor support. They returned to Total ETO and installed the newest version, which was familiar and easy to use for the staff. The implementation of Total ETO led to immediate improvements in their processes. The solution made timekeeping more efficient by allowing every employee to enter their own hours, saving accounting and payroll several hours weekly, and providing almost-live tracking to projects. It also enabled better inventory tracking, with live inventory data on the purchasing screen that could be allocated and assigned directly to projects. Leftover inventory was logged for reassignment to other projects, minimizing waste. Total ETO also provided easy reporting, allowing Keltour to quickly run reports that were easily understood.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Real-time In-vehicle Monitoring

The telematic solution provides this vital premium-adjusting information. The solution also helps detect and deter vehicle or trailer theft – as soon as a theft occurs, monitoring personnel can alert the appropriate authorities, providing an exact location.“With more and more insurance companies and major fleet operators interested in monitoring driver behaviour on the grounds of road safety, efficient logistics and costs, the market for this type of device and associated e-business services is growing rapidly within Italy and the rest of Europe,” says Franco.“The insurance companies are especially interested in the pay-per-use and pay-as-you-drive applications while other organisations employ the technology for road user charging.”“One million vehicles in Italy currently carry such devices and forecasts indicate that the European market will increase tenfold by 2014.However, for our technology to work effectively, we needed a highly reliable wireless data network to carry the information between the vehicles and monitoring stations.”

Case Study

Safety First with Folksam

The competitiveness of the car insurance market is driving UBI growth as a means for insurance companies to differentiate their customer propositions as well as improving operational efficiency. An insurance model - usage-based insurance ("UBI") - offers possibilities for insurers to do more efficient market segmentation and accurate risk assessment and pricing. Insurers require an IoT solution for the purpose of data collection and performance analysis

Case Study

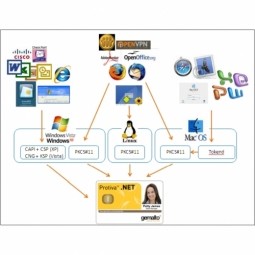

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Smooth Transition to Energy Savings

The building was equipped with four end-of-life Trane water cooled chillers, located in the basement. Johnson Controls installed four York water cooled centrifugal chillers with unit mounted variable speed drives and a total installed cooling capacity of 6,8 MW. Each chiller has a capacity of 1,6 MW (variable to 1.9MW depending upon condenser water temperatures). Johnson Controls needed to design the equipment in such way that it would fit the dimensional constraints of the existing plant area and plant access route but also the specific performance requirements of the client. Morgan Stanley required the chiller plant to match the building load profile, turn down to match the low load requirement when needed and provide an improvement in the Energy Efficiency Ratio across the entire operating range. Other requirements were a reduction in the chiller noise level to improve the working environment in the plant room and a wide operating envelope coupled with intelligent controls to allow possible variation in both flow rate and temperature. The latter was needed to leverage increased capacity from a reduced number of machines during the different installation phases and allow future enhancement to a variable primary flow system.

Case Study

Automated Pallet Labeling Solution for SPR Packaging

SPR Packaging, an American supplier of packaging solutions, was in search of an automated pallet labeling solution that could meet their immediate and future needs. They aimed to equip their lines with automatic printer applicators, but also required a solution that could interface with their accounting software. The challenge was to find a system that could read a 2D code on pallets at the stretch wrapper, track the pallet, and flag any pallets with unread barcodes for inspection. The pallets could be single or double stacked, and the system needed to be able to differentiate between the two. SPR Packaging sought a system integrator with extensive experience in advanced printing and tracking solutions to provide a complete traceability system.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data